Traditional method of making clothes of the Zeliangrong

- Part 3 -

Budha Kamei *

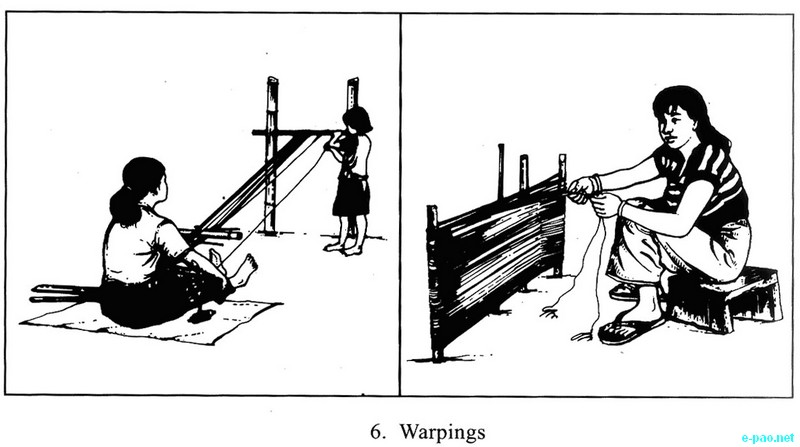

Warpings - From 'Tribal hand woven fabrics of Manipur' Book by Mutua Bahadur

Weaving is the most common method of making cloth in ancient times. Warp yarns were stretched between two beams pegged to the ground or between a tree and the weaver's waist. By 1000 B.C., weavers were using the warp-weighted looms, a vertical frame with one beam from which weighted warp yarns were hung, and the vertical two-beam loom, a vertical frame with two beams between which warp yarns were strung. The horizontal loom and the draw loom were invented in the middle Ages, probably in the Orient.

The draw loom was horizontal loom with a cord-operated device for rising and lowering the warp yarns separately, making it possible to weave intricate designs. The next major advance was the flying shuttle which was invented in 1773 by John Kay of England. It was a device for moving the shuttle by a set of cords, instead of by hand. In the early part of 1800, Joseph Jacquard of France developed the Jacquard loom, a loom with an automatic mechanism, operated by punched cards, for separately controlling the warp yarns to weave intricate designs. In 1874, English clergyman called Edmund Cartwright invented a workable power loom. Improvements in his design soon made it possible to mass produce fabrics. Since then, power looms have increased in speed, size and versatility. By the 19th century hand weaving almost had become a lost art; however, it is still used by persons in non-industrialized areas, by textile designers, by artists and persons who weave as a hobby.

The skill of weaving is one of the most essential qualifications for being a worthy girl of the Zeliangrong. It is a must for the girls to know the art of weaving in different extra weft designs. The Zeliangrong girls learn the art of weaving from their mothers and their senior ones. The art of weaving is as old as man on earth; skill is still preserved in the society by handing down through the generations from mother to daughter.

Weaving is the process of the making cloth by crossing two sets of thread over and under each other. Many fabrics and blankets, clothing and rugs are woven. Weavers may use thread spun from such natural fibers as cotton, silk and wool. The Zeliangrongs use strong man-made fibers. Narrow strips of almost any flexible material can also be woven. People learnt to weave thousands of years ago with grasses, leafstalk, palm leaves and thin strips of woods before cotton was known.

Ways of making cloths varies from one country to another. In advance countries, many kinds of machine use to make cloth and hence, manufacturing of textile can rapidly produce yarns of cotton cloth woven in many different patterns. But the Zeliangrong and other Naga tribes depend mainly on hand-power equipment for weaving cloth. The weavers create variety of designs definitely far better than the machine do. As the weaving fully does depending on hand power, it takes time.

Types of loom:

A loom is a device or machine for weaving thread or yarn into textile. Looms can be range from very small hand-held frames, to large free-standing handlooms, to huge automatic mechanical device. The Ancient Egyptians and Chinese used looms as early as 4000 B.C. The basic purpose of any loom is to hold the warp threads under tension to facilitate the inter-weaving of the warp threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

There are three types of looms in use in Manipur. They are:

(1) Loin-loom or Tension-loom or Back strip-loom

(2) Throw-Shuttle-loom

(3) Fly shuttle-loom

The earliest of these three is the loin-loom. The people probably invented this art of weaving with this loom after producing basket and mat by interlacing pieces of reed, bamboo strips or similar materials at right angles to each other. The yarns taken at perpendicular to the weaver are known as warp and the ones crossing at right angles parallel to the front of the body of the weaver as weft. Weaving on this loom is still in practice among the Nagas. The remaining two machines are mainly used among the valley Meiteis.

The loin loom or back strapped loom is the simplest and commonest technology of weaving among the Zeliangrong and other Naga tribes. It is a handloom and is known by the technical term Indonesian Tension loom. Weaving equipments like Tamben, Tamjin, Tamnukbung, Tangnam, etc. are made from the raw materials like bamboo, wood and leather. Male members help in making the weaving equipments.

Weaving equipments (Loin-loom):

(i). Back strap: Back strap is locally known as Tangnam which is made from the hide of animal. The hide is cut out enough to cover the entire back of the weaver's hip, having two loops of strong cord at the two ends. It is placed at the back of the weaver and the two loops of cord are hooked to the grooved end of the tension rod. The weaver maintains the tension of the warp by placing her feet, pressing against the foot rest.

(ii). Tension rod: It is a circular wooden rod of a meter in length and 4 cm in diameter. Its ends are grooved to take a back strap. This tension rod is called Tamjin in local dialect. The warp is wound round from the front rod to the tension rod.

(iii). Beating sword: Beating sword is made from a special kind of wood locally known as Ngai. This is made flat pointed at the one end or sometime pointed at both ends depending on the choice of the weaver. The lower edge of the beating sword is straight while the upper edge is curved. Sizes of the beating sword depend on the choice of the weaver, but as the beating sword is wielded by one arm only, its size does not exceed 6 inches in breadth and one meter in length. Zeliangrong people call it Tamben.

(iv). Front rod: It is a circular bamboo bar which is securely tied to the wall of the house or any suitable place to form a support in a horizontal position at a height of about 2 ½ feet from the ground. The length and breath of circular bar differ according to the size of the warp. Front rod is locally recognized as Tambang.

(v). Designing heddle: It has the shape and length as beating sword but smaller in size. It is made of bamboo and is used for depicting designs. This is locally called Hu Tamben.

(vi). Stretcher: Stretcher is a small flat bamboo used to pierce through the woof on both the edges. It is moved upward every twelve shedding to maintain equal breadth. This stretcher is grooved on both sides so that only the small pointed pins into the woof. This is locally known as Singkap.

(vii). Harness rod: It is a round piece of wood of a metre in length and one cm in diameter. The rod is pointed at the other end and is known as Nhu. This rod is used for lifting a set or group of yarn to form shed with the help of the harness. It is placed in front of the Tamnukbung towards the weaver.

(viii). Circular bamboo rod: This rod has one meter in length and 7 centimeter in diameter. The yarn passing over and under the bamboo makes an opening and this is used as one shedding while the lifting of yarn with the harness rod acted as another shedding. This bamboo is called Tamnukbung.

(ix). Lease rod: It is a circular rod of wood exactly like the harness rod which is placed after the bamboo rod (Tamnukbung). It is a little bit longer than the bamboo rod. This is locally known as Rai. It checks the yarn from getting entangle.

(x). Wax: Diuga is prepared from beehive. The hive is pounded in the mortar and made an oval shape lump enough for handling. Wax is used to rub on the warp thread to prevent from moist and being stapled. Sometimes, it is used as a warp brush by inserting pig's hair in the wax.

(xi). Foot rest: A stout beam as a foot rest called Phaipan is placed against the wall of the house or post and towards the feet of the weaver. It is then, adjusted according to the warp length and the weaver's leg by placing more wooden logs.

To be continued..

* Budha Kamei wrote this article for The Sangai Express

This article was posted on November 26 , 2014.

* Comments posted by users in this discussion thread and other parts of this site are opinions of the individuals posting them (whose user ID is displayed alongside) and not the views of e-pao.net. We strongly recommend that users exercise responsibility, sensitivity and caution over language while writing your opinions which will be seen and read by other users. Please read a complete Guideline on using comments on this website.